With limitless customization capabilities, our engineers will deliver the ideal lift for your needs with efficiency and safety always built in.

Work PositionersBuild for Precision and Productivity

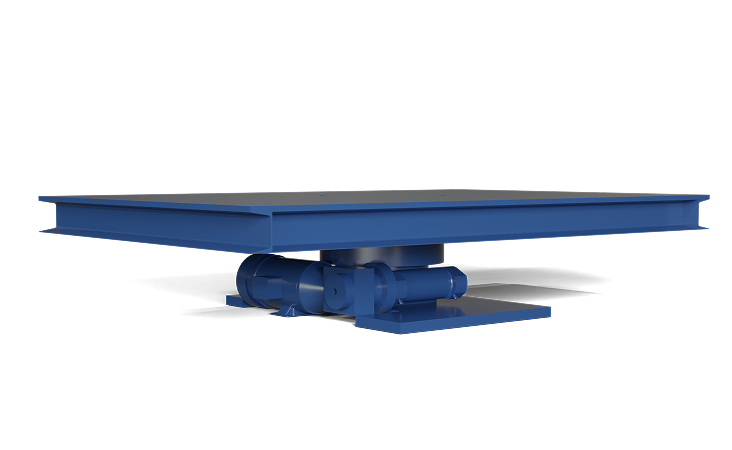

Autoquip Work Positioners are designed to improve workflow, reduce strain, and increase productivity across various industrial uses. Our ergonomic lift systems, including tilters, turntables, and pallet handling solutions, are built to position parts, tools, and assemblies into the ideal working position. With superior engineering and extensive customization options, Autoquip boosts safety and efficiency for operators at all levels.

Advantages ofAutoquip Work Positioners

- Ergonomic designs reduce operator fatigue and injury risk

- Smooth, controlled positioning for improved throughput

- Compact footprint fits into tight production spaces

- Ideal for lifting, rotating, tilting, or lowering materials

- Built for repetitive tasks in industrial, warehouse, and manufacturing settings

Factors to Consider When Selecting a Work Positioner

Autoquip Work Positioners are ideal for assembly lines, packing stations, and inspection tasks, ensuring optimal access and comfort in every application. When evaluating work positioners, consider the following questions to guide your decisions.

- What are the dimensions and weight of the items being handled?

- How will the positioner be used throughout the day?

- Do I need tilt, rotate, or lift capabilities? Or all three?

- What safety and control features are required?

The AutoquipAdvantage

With over 75 years of experience, we understand that one size does not fit all when it comes to industrial lifts. Our highly skilled team of engineers and technical experts maintain a reputation for taking on diverse specialized projects and delivering exceptional results. That’s why our industry-leading design and fabrication services are able to deliver the best solution for any application.

Expect More With Autoquip Work Positioners

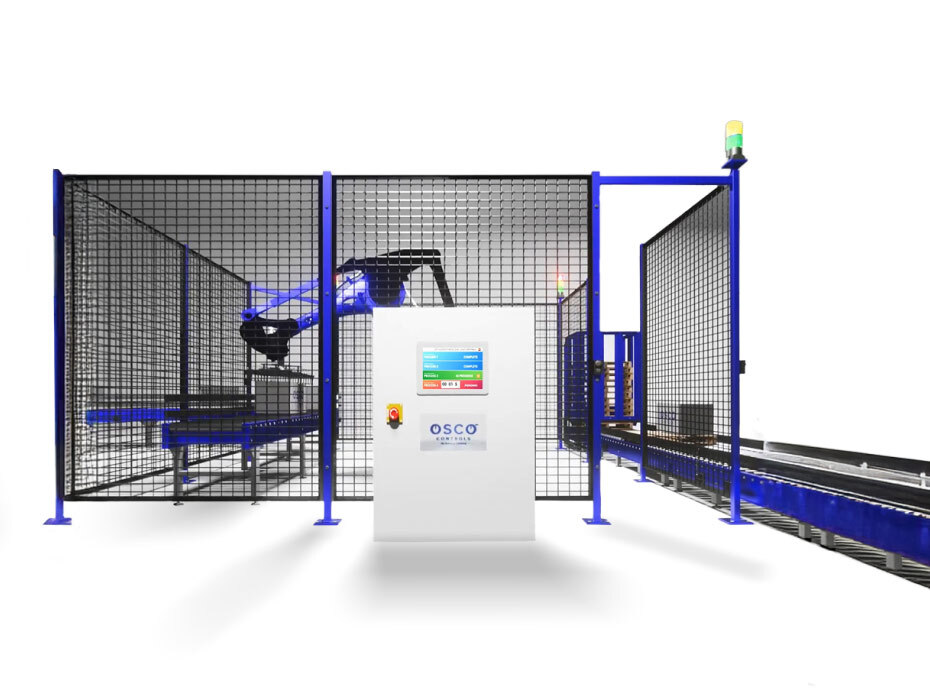

- Integrated controls for simple or complex workflows

- Optional automation and feedback systems

- Custom motion configurations

- Heavy-duty construction for industrial reliability

- Compliance with ergonomic and safety standards

- Seamless integration with material handling systems

Customized to Fit Your Floor & Process

No two workstations are the same. That’s why Autoquip engineers custom work positioners built around your unique task flow, load requirements, and space constraints. From rotating turntables to tilt functionality, we’ll configure the perfect solution for safer, more productive work environments.

- Turntables and tilt platforms

- Foot-activated or push-button controls

- Variable platform sizes and weight capacities

- Washdown-ready or food-grade finishes

- Load leveling and programmable heights

ProjectExperience

Our lifts are trusted across industries for a reason. See our work positioners in action.

Frequently Asked Questions

Yes. At Autoquip, we specialize in custom-engineered work positioners. We work closely with you to tailor the design—whether it’s platform size, load capacity, rotation or tilt angle, or integration with your workflow.

We offer a wide range of custom design options.

- Platform size and shape

- Load capacity (light to heavy-duty)

- Rotation (manual, powered, 90° to 360°)

- Tilt range (up to 90°)

- Mounting configurations (floor-mounted, pit-mounted, integrated into lift platforms)

- Control types (push-button, foot pedal, PLC, remote)

Absolutely. We can integrate turn tables and tilters with scissor lifts or custom lift platforms to create multi-function workstations that raise, rotate, and tilt materials for optimal ergonomic access.

Yes. Our positioners can be equipped with automated controls, programmable logic controllers (PLCs), position sensors, and integrated with other equipment in your facility for seamless material handling.

Our custom turn tables and tilters are used across automotive, aerospace, manufacturing, warehousing, and assembly lines, where ergonomics, precision, and throughput are critical.

We incorporate the following application-specific safety measures.

- Toe guards and protective skirts

- Maintenance props

- Safety interlocks and e-stop controls

- Load sensors and position indicators

Explore More Autoquip Solutions

Get In Touch With Our Experts

Ready to improve your workflow? Contact our team to start your project or request a quote today.

Talk to an Expert