With limitless customization capabilities, our engineers will deliver the ideal lift for your needs with efficiency and safety always built in.

Autoquip High-Capacity LiftsEngineered to Lift the World's Heaviest Loads

Autoquip delivers exceptional high‑capacity lift solutions, expertly engineered for lifting needs starting at 8,000 lb. and scaling up to 135,000 lb. (and even up to 300,000 lb. for in‑ground ram installations). From robust scissor lifts to heavy‑duty ram and inground vertical lift systems, Autoquip offers reliable performance across large industrial, manufacturing, assembly, staging, and vehicle maintenance applications.

Advantages ofHigh-Capacity Lifts

- Efficiently lifts oversized loads up to 300,000+ lbs.

- Constructed with heavy-duty steel frames, premium cylinders, and components

- Overload protection and safety features

- Custom-configured solutions for platform size and load distribution

- Proven reliability in automotive, aerospace, defense, and industrial settings

Factors to Consider When Choosing Your High-Capacity Lifts

A high-capacity lift is a powerful tool that requires a thorough understanding of your application’s needs and your facility’s space and infrastructure requirements. When evaluating High-Capacity Lifts, consider the following questions to guide your decision.

- What’s the weight and size of the loads I need to lift?

- What is the cycle frequency?

- What type of environment will it operate in?

- What is the load profile – size / shape of load?

- Do I need to integrate the lift with other systems?

- What safety and control features are required?

Autoquip Advantage The Leader in High-Capacity Lifts

With over 75 years of experience, we understand that one size does not fit all when it comes to industrial lifts. Our highly skilled team of engineers and technical experts maintain a reputation for taking on diverse specialized projects and delivering exceptional results. That’s why our industry-leading design and fabrication services are able to deliver the best solution for any application.

Expect More With Autoquip High-Capacity Lifts

- Engineered for strength and reliability, capable of handling loads up to 300,000 lbs.

- Custom options to improve functionality for your unique application

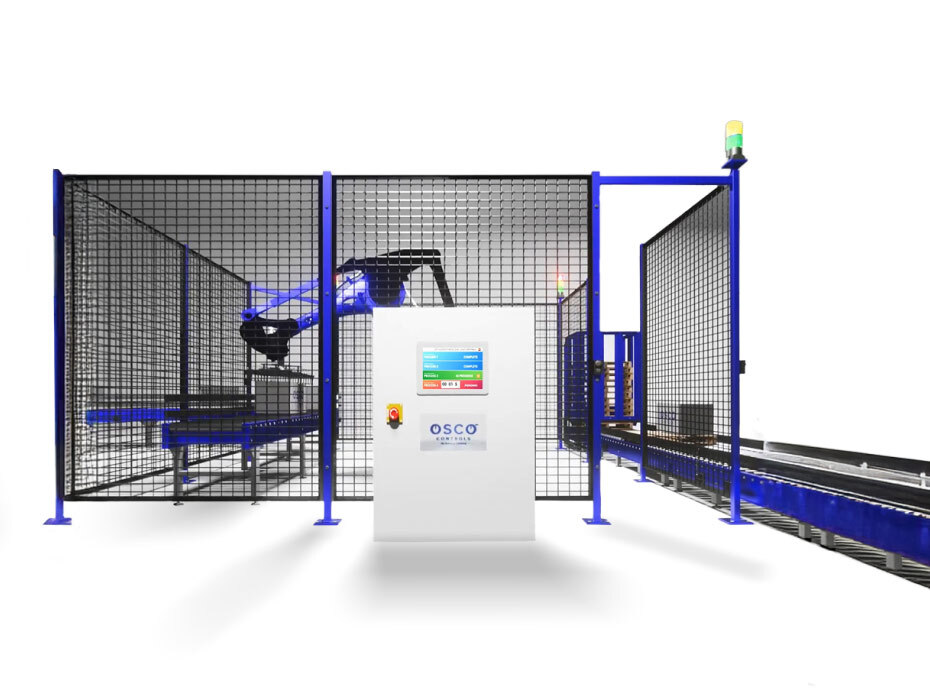

- Seamless integration with conveyor systems, AGVs, and robotics

- A team with extensive background in advanced engineering capabilities

- Access to the industry’s largest design library

- Streamlined operations with an intelligent control panel system

Custom Solutions for Complex Lifting Challenges

No two heavy-duty operations are the same, and neither are our lifts. Autoquip’s experienced engineers develop custom high-capacity lift systems tailored to your exact load specs, height range, operational footprint, and integration needs. Whether you need automated platforms, extra-wide bases, or advanced safety features, we build solutions that move your operation forward.

ProjectExperience

Built with reinforced steel structures and premium components, our high-capacity lifts are designed to withstand extreme loads and operate continuously in demanding environments. Learn how we’ve helped customers improve their operations with our high-capacity lifts.

Frequently Asked Questions

Autoquip high-capacity lift solutions are engineered to handle extremely heavy loads—from 8,000 lb. up to 135,000 lb. for scissor lifts, and up to 300,000 lb. for in-ground hydraulic ram lifts.

Heavy-duty scissor lifts, like our Super Titan series, are ideal for above-ground applications requiring platform customization and vertical travel. In-ground ram lifts offer permanent, pit-mounted solutions for extreme load handling in space-constrained environments.

Yes. Every high-capacity lift system we build can be custom-engineered for your exact load dimensions, platform size, height range, and integration needs.

We offer a wide range of platform configurations, including double-wide, quad, and extra-wide/double-long options. Platforms can also be integrated with conveyors, turntables, and other equipment.

Autoquip offers single-ram and dual-ram in-ground hydraulic cylinder configurations. Single-ram lifts are ideal for centered, concentrated loads, while dual-ram systems are designed for longer or unevenly distributed loads. Our dual-ram configurations feature precision cylinder synchronization, ensuring smooth, level lifting. These lifts are ideal for permanent pit installations in demanding industrial environments where high stability and lifting accuracy are critical.

Installing an in-ground ram lift requires a permanent pit installation that meets the system’s depth, width, and structural support specifications. Autoquip provides detailed pit drawings and engineering support to ensure proper preparation.

Explore More Autoquip Solutions

Get In Touch With Our Experts

Ready to improve your workflow? Contact our team to start your project or request a quote today.

Talk to an Expert