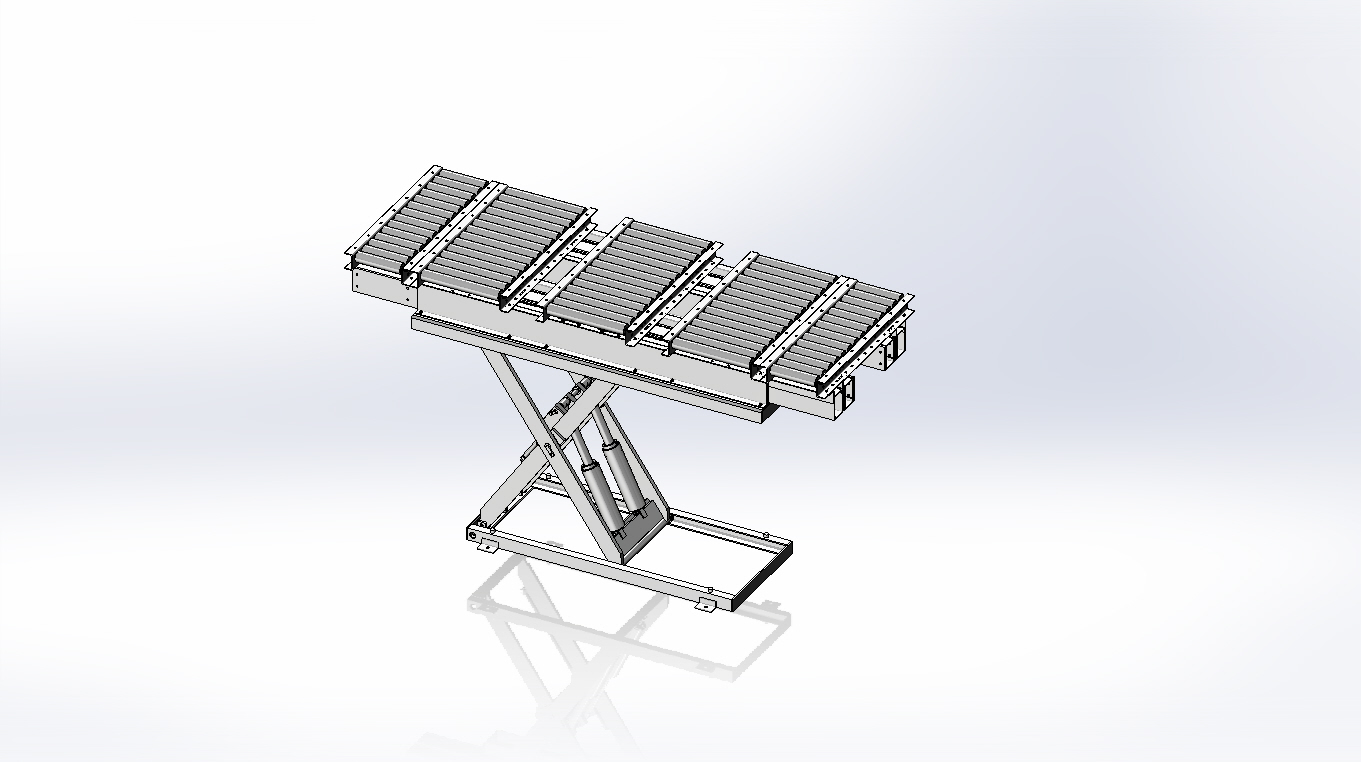

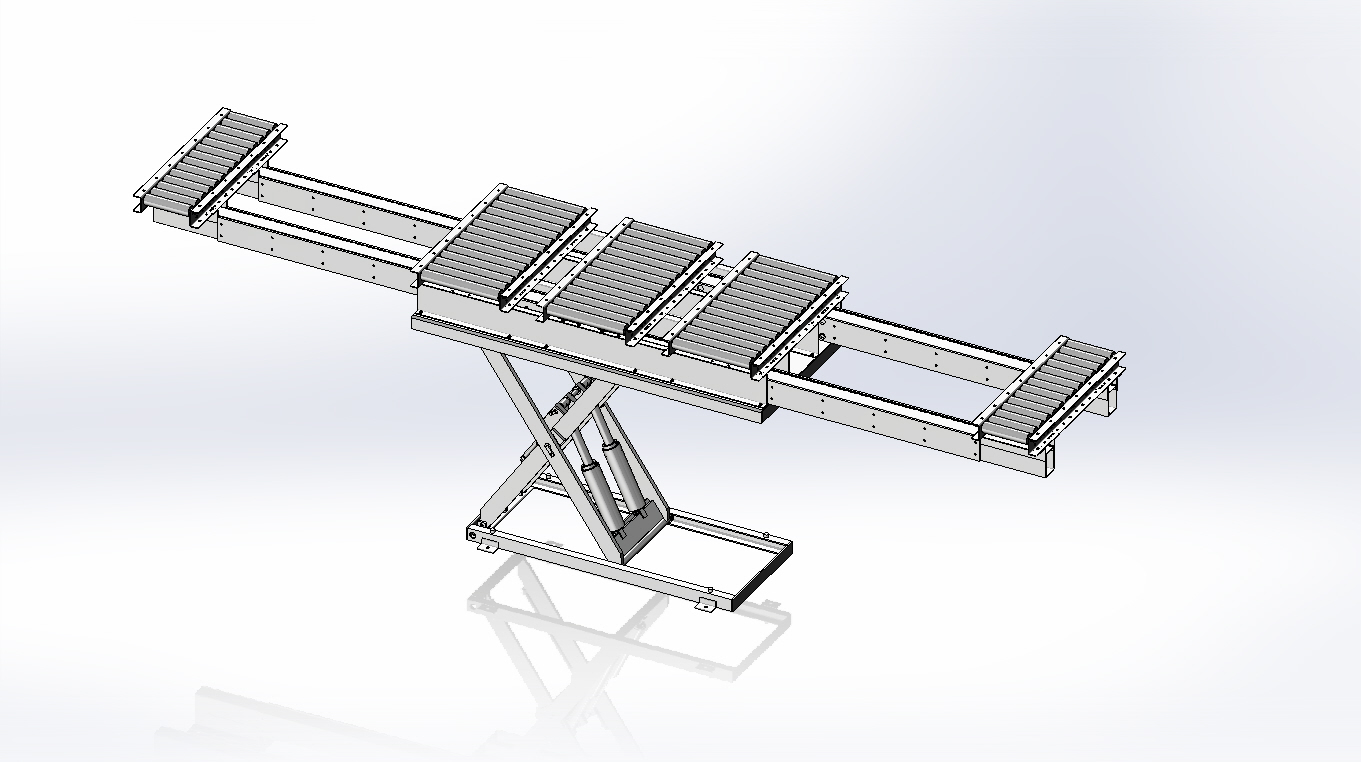

Sectional Conveyor Lift System

Introduction

Sectional Conveyor Lift System Adjustable to Size Ranges of Aluminum Extrusions

Project Challenge

Our dealer, WW Grainger brought us the opportunity to work with Pennex Aluminum on an application to replace sections of permanent conveyors. They wanted a solution to make stacking the aluminum extrusions more ergonomically friendly.

Our Solution

Autoquip provided a Tork scissor lift with conveyor sections for receiving and stacking the extrusions while adjusting the level the lift. The lift platform is designed with the ability to extend or slide out sections to accommodate the many ranges of lengths in the aluminum extrusions. The platform mounted gravity conveyors are spaced to allow forklift access to the load when the stack is complete. The lift unit is equipped with pneumatic / hydraulic power unit that works off shop supplied air and controlled by a footswitch.

AQ Project#

151957

The Results

Autoquip’s in-house design and engineering team provided a lift conveyor solution that replaced an outdated system with new lifting technology that is adjustable to the application and provides an ergonomically benefit.