Custom Lift System for Forklift Drive-Over Application

Introduction

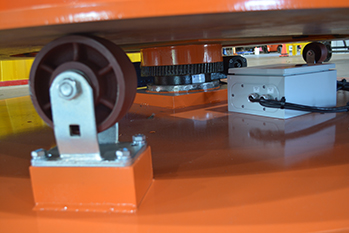

Special lift system with support structure and turntable accommodates unique loading process.

Project Challenge

This application required a different approach for a forklift loading process. The forklift will drive over the edge of the system that sits sub-floor while loading takes place. The scissor lift travels above grade and the system is rotational to accommodate the application process.

Our Solution

To accommodate this unique application we built this lift system with a support structure around the Tork scissor lift and a turntable that sits underneath the sub-floor to rotate the system at 2 RPM. The structure around the system helps supports the load while also accommodating the onboard power unit and control panel. The power unit includes an anti-drift down valve.

Other features include:

- 10,000 lb. capacity

- (2) Maintenance hatches and devices.

- (2) Proximity switches mounted and wired, set to full travel and set at grade level.

- Safety signal – red flashing light while in use.

- Control Panel designed with VFD to provide ramp up and ramp down for turntable.

- Slip ring used in turntable for power to lift power unit.

- Control panel programmed for up/down, clockwise/counterclockwise

- Sensing edge around platform edge and pit edge for toe protection.

Model Info. – TRK-048-0100-T1SP

AQ Project#

9TRK-53811-2

The Results

Autoquip has an unrivaled reputation for building unusual – special lifts to accommodate unique applications. With the newly installed lift system the company is now able to drive the forklift onto the structure with more precise control and stability. The team at Autoquip completed weight and functional tests for the customer prior to shipping to prove the lifting process and capacity.