Modular VRC Systems: The Future of SLAM Integration and Smart Warehousing

Warehouses are evolving at lightning speed, and your vertical material handling needs to keep up. Modular VRC systems are at the heart of this transformation, enabling seamless SLAM integration, smarter automation, and scalable growth. In this guide, you’ll see how Autoquip’s modular lift design is redefining what’s possible for automated material handling and future-ready warehousing.

Here’s what you’ll learn:

- How Modular VRC Systems Streamline SLAM Integration: Why modular lifts are the backbone of high-speed Scan, Label, Apply, Manifest (SLAM) processes.

- Key Features of Modular Lift Design: Plug-and-play, scalable VRCs that flex as your business grows.

- The Business Value of Modular VRCs: Measurable ROI, labor savings, and space optimization.

- Real-World Results: SLAM Process Case Study: How a leading retailer leveraged Autoquip’s modular VRCs for rapid, low-disruption installation and repeat success.

- Innovation Spotlight: QuickStack Modular VRC: Autoquip’s latest modular VRC innovation for rapid deployment and flexibility.

- Why Autoquip Leads in Smart Warehousing Innovation: What sets Autoquip’s modular VRC systems apart in reliability and integration.

Want to see how modular VRC systems can transform your SLAM area? Connect with Autoquip for a custom consultation and discover the next generation of smart warehousing.

How Modular VRC Systems Streamline SLAM Integration

In today’s e-commerce-driven world, SLAM (Scan, Label, Apply, Manifest) areas are the nerve center of fulfillment. As order volumes surge and product mixes diversify, traditional lifts and static systems simply can’t keep up. Modular VRC systems are engineered to bring new levels of speed, flexibility, and reliability to SLAM integration, helping warehouses move faster and smarter.

The ability to move materials vertically with minimal disruption is essential for modern fulfillment centers. Whether you’re handling thousands of parcels per hour or adapting to new product lines or storage requirements, modular VRCs enable you to optimize your SLAM process for both present and future needs. These systems are designed to integrate with the latest automation technologies, ensuring your facility remains competitive as the industry evolves.

SLAM Integration Demands Agility

Modern SLAM zones are high-speed, high-volume environments. Integrating mezzanines, conveyors, and automation is critical, but these needs are constantly changing. Modular lift design lets you reconfigure, expand, or upgrade your vertical material handling with minimal downtime, supporting everything from seasonal surges to long-term growth. As fulfillment operations become more complex, the ability to adapt quickly is a clear competitive advantage.

Key Features of Modular Lift Design for Automation and Adaptability

Unlike traditional vertical lifts, modular VRCs are engineered for rapid deployment and seamless integration. Their plug-and-play architecture means you can connect new lifts to existing automation, conveyors, or WMS platforms without lengthy construction or workflow disruption.

Key Features of Autoquip’s Modular VRC Design

- Plug-and-Play Controls: Intuitive controls for rapid installation and integration with WMS, conveyors, and robotics. Operators can quickly learn and adapt to the system, reducing training time and ensuring smooth transitions.

- Customizable Carriage & Structure: A range of carriage sizes, platform options, and safety features to fit your exact needs. Whether you’re moving small packages or heavy pallets, modular VRCs can be tailored to your operation.

- Scalable & Reconfigurable: Add or reconfigure lifts as your business grows; no major construction required. This is especially valuable for facilities that experience seasonal peaks or rapid growth.

- Smart Integration: Engineered for AGVs, AMRs, and conveyor systems to support fully automated workflows. Modular VRCs can communicate with other intelligent systems, enabling real-time inventory tracking and process optimization.

- Durable, Low-Maintenance Construction: High-quality materials and modular subassemblies for maximum uptime. Components are designed for easy access and replacement, minimizing downtime for maintenance.

- Advanced Safety and Compliance: Multiple safety layers and compliance with ANSI, OSHA, and local codes. Features such as interlocked gates, emergency stops, and overload sensors ensure safe operation in busy environments.

- Ready-to-Connect Deployment: Each modular VRC is pre-fabricated and delivered in sections, arriving ready to connect for faster, less disruptive installation. This approach means less on-site construction and a smoother project timeline.

This modular approach means your VRC can evolve alongside your business, supporting everything from new product lines to facility expansions. It gives you the flexibility to adapt to shifting market demands or seasonal peaks, ensuring your material handling infrastructure never holds you back.

For operations managers and engineers, these features translate to less time spent on installation and troubleshooting, and more time focused on optimizing throughput and safety.

The Business Value of Modular VRCs in Automated Material Handling

The real power of modular VRC systems lies in their ability to deliver measurable business benefits across every dimension of warehouse performance. By enabling rapid installation, seamless integration with automation, and easy scalability, modular VRCs help warehouses respond quickly to changing demands and growth opportunities. They support higher throughput, reduce manual labor, and optimize vertical space while maintaining safety and compliance. For operations teams, this means less downtime, lower operational costs, and the flexibility to adapt material handling processes as business needs evolve.

Operational Advantages of Modular VRCs

- Accelerate Fulfillment: Automated vertical movement eliminates bottlenecks and keeps SLAM areas stocked, allowing for faster order processing and improved customer satisfaction.

- Reduce Labor and Training Costs: Automation frees up staff and minimizes training requirements, allowing your workforce to focus on value-added tasks.

- Maximize Space Utilization: Expand capacity vertically without expanding your facility’s footprint, making the most of your available real estate.

- Minimize Downtime: Install or upgrade lifts without shutting down your operation, ensuring continuous productivity.

- Adapt to Change: Rapidly reconfigure your systems as business needs shift, whether you’re adding new SKUs or adjusting to seasonal demand.

- Enhance Safety: Reduce manual lifting risks and protect your workforce, leading to fewer injuries and lower insurance costs.

- Drive ROI: Labor savings, space optimization, and throughput gains deliver rapid payback, making modular VRCs a wise long-term investment.

Ultimately, modular VRC systems empower facilities to achieve greater efficiency, reliability, and long-term value in an increasingly competitive logistics landscape. By choosing modular VRC systems, warehouses position themselves for long-term success, with the ability to scale, adapt, and stay ahead of the curve as industry demands change.

Real-World Results: SLAM Process Case Study

When a major online retailer needed to ramp up distribution and streamline their SLAM process, it turned to Autoquip for help. The solution featured a modular mechanical cantilever freight lift, pre-engineered and pre-fabricated at Autoquip’s facility, then delivered ready to connect in three sections. Installation was completed faster than with traditional VRCs, with minimal disruption to ongoing operations.

The modular freight lift provided a durable, easy-to-use solution for moving packing materials to the mezzanine SLAM area. The customer praised the lift’s performance and ease of use, leading to additional orders and a long-term partnership. This approach not only reduced installation time and cost but also demonstrated the versatility of modular VRCs for SLAM and other material handling applications. Read the complete case study.

Because Autoquip’s modular VRCs are engineered for “ready-to-connect” deployment, they can be included in any distribution center’s SLAM area or adapted for a wide range of warehouse and material handling processes.

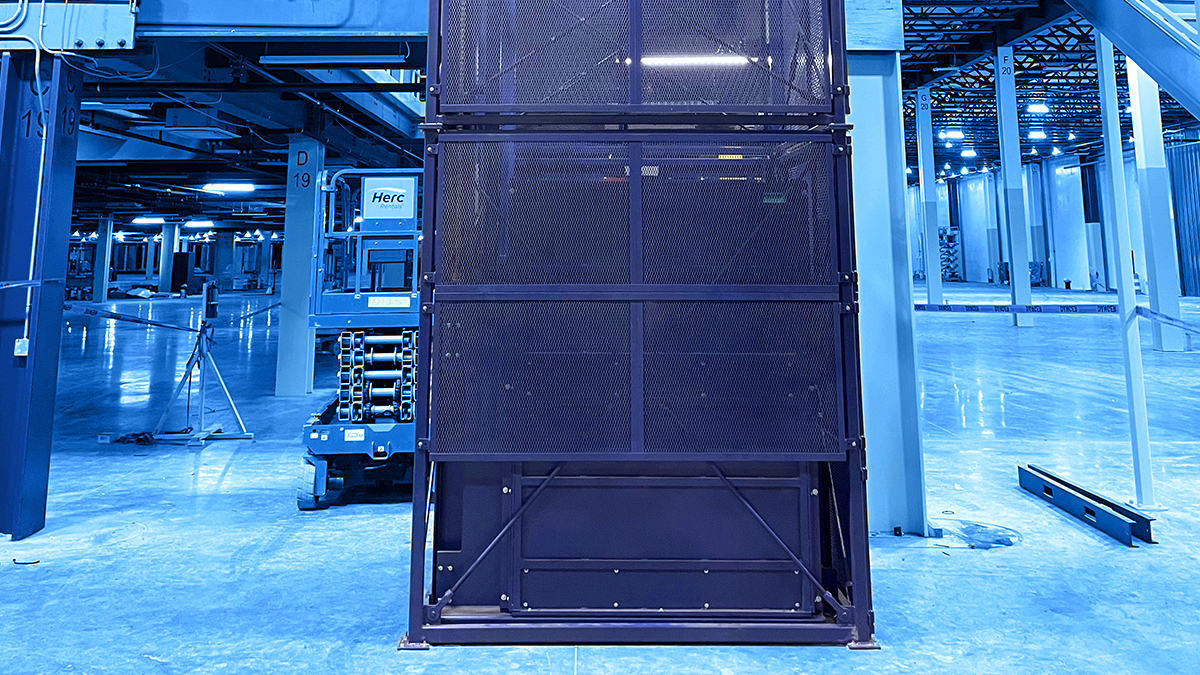

Innovation Spotlight: QuickStack Modular VRC

Building on decades of modular lift expertise, Autoquip introduced the QuickStack Modular VRC, a breakthrough designed for even faster deployment and maximum flexibility. QuickStack’s compact, modular construction and ready-to-connect design make it ideal for modern SLAM areas and evolving warehouse environments.

Why QuickStack Sets a New Standard

QuickStack’s design is built for the realities of today’s dynamic warehouses, offering unmatched speed, flexibility, and integration. Here’s what sets it apart:

QuickStack Modular VRC highlights:

- Fast, Low-Disruption Installation: Pre-engineered sections and plug-and-play controls mean QuickStack can be installed with minimal downtime, making it perfect for facilities that can’t afford to pause operations.

- Modular Components for Expansion: As your needs change, QuickStack can be expanded or reconfigured quickly-without major construction or workflow interruption.

- Advanced Safety Features: QuickStack meets or exceeds the latest industry standards, with built-in safety gates, interlocks, and overload protection.

- Automation-Ready: Designed for compatibility with a wide range of conveyor, WMS, and robotics systems, QuickStack supports the most advanced smart warehousing applications.

- Energy-Efficient Operation: Engineered for low power consumption, QuickStack helps reduce operational costs while supporting sustainability goals.

QuickStack represents the next generation of modular VRC systems, providing warehouses with the agility to scale and adapt as business needs change. Whether you’re planning a new facility or upgrading an existing one, QuickStack offers a future-ready solution that keeps your operation competitive.

Why Autoquip Leads in Smart Warehousing Innovation

Autoquip’s leadership in modular VRC systems is built on a foundation of innovation, engineering excellence, and a relentless focus on customer success.

- Decades of Experience: Over 75 years of vertical lift technology leadership and real-world expertise.

- Relentless Innovation: Ongoing R&D delivers smarter controls, new features, and seamless integration.

- Custom Engineering: Every modular VRC is tailored to your facility, workflow, and automation ecosystem.

- Advanced Controls and Integration: OSCO Controls, a proven leader in the custom control vertical, is an integral member of the Autoquip family. Their advanced approach to control systems enables plug-and-play connectivity with WMS, AGVs, AMRs, and more.

- Comprehensive Support: From initial design to ongoing service, Autoquip’s team is with you every step of the way.

- Made in the USA: Designed and manufactured in Guthrie, Oklahoma, with a reputation for reliability and long-term value.

When you choose Autoquip, you’re not just investing in equipment – you’re partnering with the leader in modular VRC systems for automated material handling and innovative warehousing. Our commitment to quality, innovation, and customer satisfaction ensures your facility is always ready for what’s next.

Future-Proof Your SLAM Area with Modular VRC Systems from Autoquip

Don’t let outdated lifts or rigid systems hold back your fulfillment operation. Modular VRC systems from Autoquip empower you to adapt, scale, and thrive, no matter how your business evolves.

Ready to unlock the power of modular VRCs for your SLAM integration? Contact Autoquip for a free quote and discover the next generation of smart warehousing.

Take the Next Step Toward Agile, Automated Material Handling

Modular VRC systems are more than a trend- they’re the key to building a flexible, future-ready warehouse. By embracing modular lift design and seamless SLAM integration, you position your operation for greater efficiency, lower costs, and sustained growth. With Autoquip’s expertise and innovative solutions like QuickStack, your facility can meet today’s demands and tomorrow’s challenges with confidence.

Let’s build the future of automated material handling together. Reach out to Autoquip today and see how modular VRC systems can transform your SLAM area and beyond.