Modern Warehouse Equipment: Benefits of Scissor Lift Tables

In today’s fast-paced warehouse environments, staying competitive means finding ways to enhance both productivity and safety. With growing demands for quicker turnaround times and the need to optimize every square inch of space, facilities must rely on warehouse equipment that can keep up with these challenges.

Scissor lift tables have become a vital solution for businesses aiming to streamline material handling processes, reduce workplace injuries, and improve overall workflow. These reliable lifting tools offer precise height adjustments, making them ideal for a variety of tasks, from loading and unloading materials to product assembly line support. Facilities looking to buy versatile warehouse equipment find scissor lifts essential for daily operations.This post explores the many ways these flexible lifts deliver efficiency improvements and safety benefits in warehouse settings.

Contact Autoquip to discuss your warehouse needs. We’ll help you find the perfect scissor lift table solution for your facility.

Create a Next-Level Warehouse with Scissor Lift Tables

Savvy warehouse managers understand that a safe and productive environment is the key to operational success. Scissor lift tables offer a reliable and effective way to handle heavy loads, reduce strain on workers, and increase overall efficiency. With applications across diverse industries, these versatile tools help warehouses meet demand without compromising safety.

The Role of Scissor Lift Tables in Modern Warehousing

As warehouse demands change and grow, so does the need for adaptable, safe lifting solutions. Unlike other equipment, scissor lift tables can be tailored to enhance warehouse operations at multiple levels—from speeding up material handling to minimizing worker fatigue. Their adjustable height settings and sturdy platforms enable workers to handle goods of various sizes without strain, making them a valuable asset for any facility looking to modernize its operations. With the capacity to lift and lower materials seamlessly, scissor lifts facilitate a smoother flow of products and reduce the bottlenecks that can slow down productivity.

Advantages of Scissor Lift Tables in Warehouse Settings

Enhancing Workplace Safety Solutions through Ergonomics

One of the most critical concerns in any warehouse is maintaining a safe environment for workers. Manual lifting and awkward postures are common causes of workplace injuries, leading to costly downtime and medical expenses. Scissor lift tables help mitigate these risks by allowing workers to position loads at ideal heights, reducing the need for bending, overreaching, or ticky lifting. This ergonomic advantage means that operators can focus on their tasks without physical strain, which contributes to higher morale and fewer injury-related absences.

Boosting Productivity with Seamless Material Handling

Efficiency is the heartbeat of successful warehouse operations. By integrating scissor lift tables, businesses can dramatically reduce the time spent on moving and handling materials, especially when working with shelving and racking configurations. Unlike traditional methods, where workers might spend valuable time adjusting their position or handling cumbersome loads, scissor lift tables streamline these processes. This translates to faster loading and unloading times, quicker access to inventory, and overall smoother material handling operations.

For warehouses managing large volumes of inventory, these improvements can lead to significant time savings and increased throughput. As a result, facilities can meet deadlines easier and accommodate higher volumes of products without adding extra shifts or labor hours.

Versatility in Application: Meeting Diverse Warehouse Equipment Needs

One of the standout features of scissor lift tables is their versatility. As crucial pieces of warehouse equipment, they can be adapted to various applications within a warehouse, from lifting heavy pallets to aiding in the manufacturing process. Their adaptability also makes them suitable for tasks such as product stacking, ergonomic work positioning, and even supporting packaging lines.

With different models and capacities available, businesses can select the right scissor lift to match their specific needs. For example, a warehouse that processes heavy automotive parts may benefit from a high-capacity scissor lift. At the same time, a facility handling lighter consumer items could use a more compact model for quicker adjustments. This flexibility ensures that warehouses are investing in equipment that aligns seamlessly with their operational goals.

Lower Maintenance, Higher Longevity

In addition to their operational benefits, scissor lift tables from Autoquip are designed with durability in mind. These tables are built to run at high levels of performance, withstanding the rigors of daily warehouse operations. The simple yet robust design means fewer moving parts, which translates into lower maintenance requirements and reduced downtime. For warehouse managers, this means less time and money spent on repairs, allowing them to focus on core operations.

The long-term reliability of our scissor lift tables makes them a cost-effective solution for warehouses looking to invest in quality equipment that will serve them well into the future. This reliability also means that businesses can avoid the frequent replacements that are often required with less durable lifting equipment, providing additional savings over time.

Customization for Unique Warehouse Systems

One of the strengths of Autoquip’s scissor lift tables is the ability to customize each model to suit the specific requirements of a warehouse. Whether it’s the height range, platform size, or load capacity, Autoquip works closely with clients to design solutions that integrate seamlessly into existing workflows. And with a library of over 1000 models to choose from, your customization options are limitless.

Custom options like tilt and turn, automation, or specialized controls can further enhance the functionality of a scissor lift table, ensuring that it meets your operational needs. With Autoquip, you never have to compromise on your requirements; just tell us what you need. Our team will partner with you to ensure your new table maximizes productivity while ensuring that it’s a perfect fit for your environment.

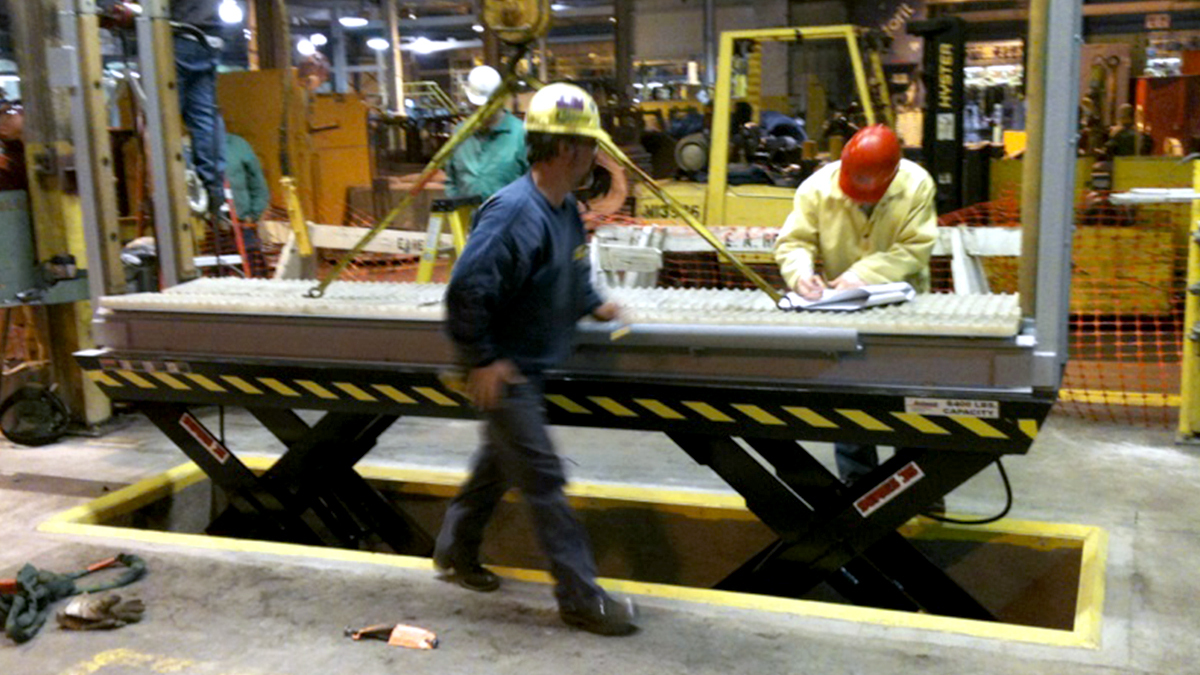

Real-World Success: Transforming Heavy Lifting for Greater Warehouse Efficiency

Tasked with creating a solution for a client requiring efficient movement of extremely heavy materials, Autoquip developed a custom scissor lift to handle large loads with precision. This tailored solution not only simplified the handling of inventory in a two-level warehouse but also improved safety and productivity on the work floor. This case study illustrates how the right scissor lift can make a transformative difference in demanding warehouse environments. At Autoquip, we’re creating custom lift systems that solve unique problems every day.

Take the Next Step Toward a Safer, More Efficient Warehouse

In the dynamic world of warehousing, productivity and safety are crucial. Autoquip specializes in providing scissor lift tables that streamline your material handling workflows, reduce downtime, and enhance overall productivity. With our solutions, you can streamline workflows and boost your bottom line. Whether you’re looking to improve ergonomics, organize pallet storage, increase throughput, or design customized lifting solutions to meet your unique application, Autoquip has the expertise that delivers the results you’re looking for.

Autoquip has over 70 years of experience in building, implementing, and supporting advanced lifting solutions for warehouses across various industries. With our deep knowledge of industry requirements and a commitment to quality, we’re ready to partner with you to create the ideal solution for your facility.

Optimize your warehouse operations and future-proof your material handling capabilities with our scissor lift tables. Request a free quote today, and let’s explore customized options that align with your unique operational needs.

Why Scissor Lift Tables Are Essential for Warehouse Operations

Investing in scissor lift tables is a strategic choice for businesses seeking to upgrade their warehouse equipment, support efficient operator workflows, and improve productivity. These versatile lifts not only enhance efficiency but also provide ergonomic benefits that protect workers from injury. As demands increase, having equipment like scissor lift tables ensures warehouses can meet expectations without sacrificing quality or safety. The combination of durability, customization options, and proven results in real-world applications makes scissor lift tables an invaluable asset for any warehouse looking to stay competitive in today’s market.

Contact Autoquip today to learn more about how our scissor lift tables can optimize your warehouse.