Applications

Wash Down

Special attention must be given to equipment exposed to water. Consideration must be given to all primary design features to ensure water will not prematurely disable or destroy the equipment or result in personnel injury. Available material lift design solutions protect critical features such as the electrical circuit and components, hydraulic fluid, bushings and bearings, and paint finish.

Experience & Expertise

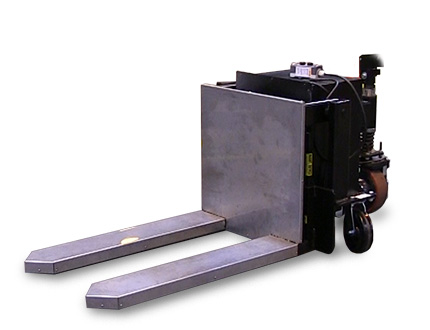

Lifting and handling solutions Autoquip designed and manufactured for wash down applications include:

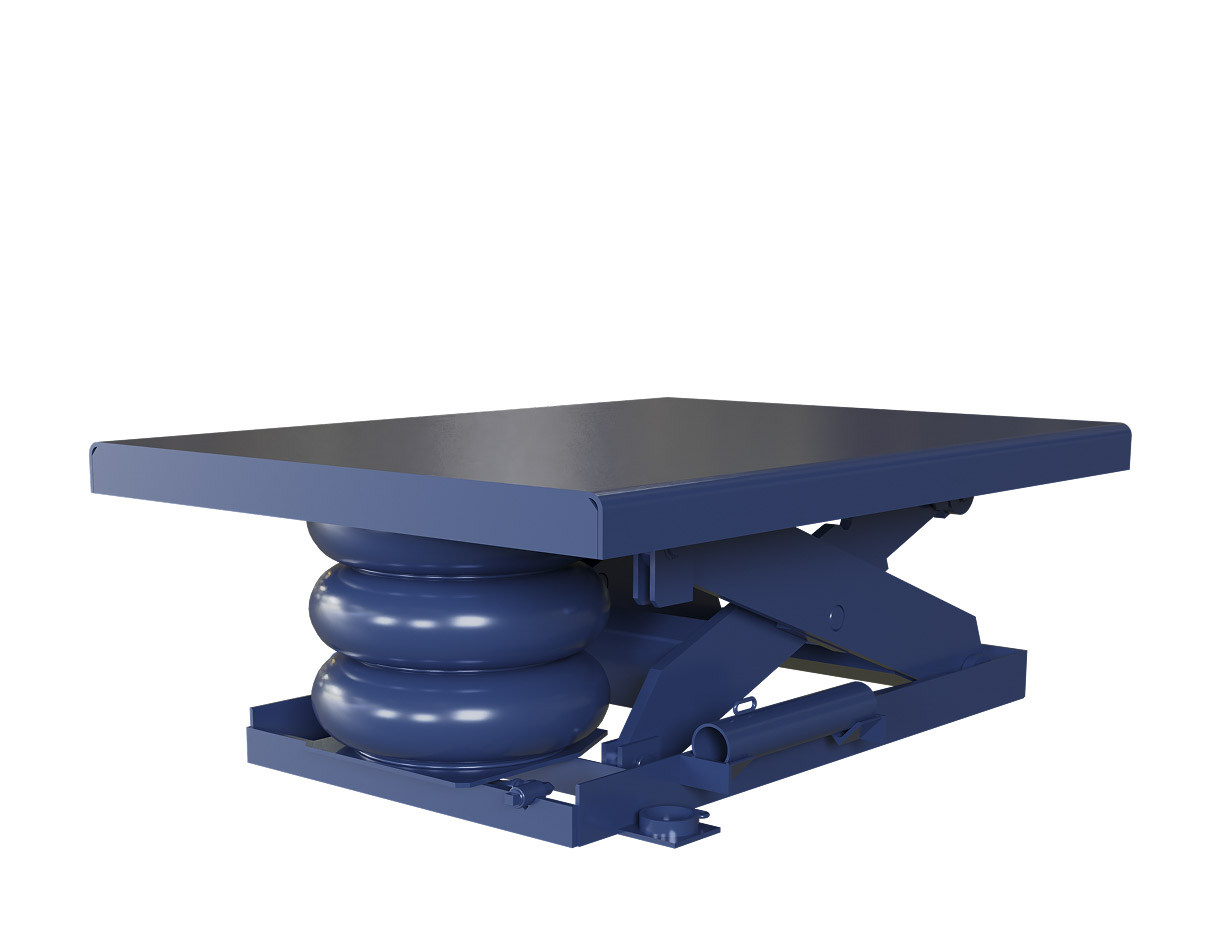

Special scissor lift tables are designed to be used in the manufacturing of chocolate.

Scissor lifts with powered turntables are painted with two-part epoxy and fitted with vinyl skirting to minimize water-spray on both power unit and drive components.

A mechanical VRC lift with Steelcote paint finish is used to transport chemicals between multiple levels in the factory.

A heavy-duty scissor lift with non-skid walking surface, waterproof controls, and a weatherproof cover was mounted outdoors in a recessed pit.

A mechanical VRC lift was installed outdoors, allowing roof access to maintenance tools and equipment. The drive unit has a cover to minimize exposure to wind-blown rain.

Special scissor lifts are used to transfer vehicles from garage level to basement level and are given a powder coat finish to minimize rust and corrosion when vehicles came in from rain and snow.