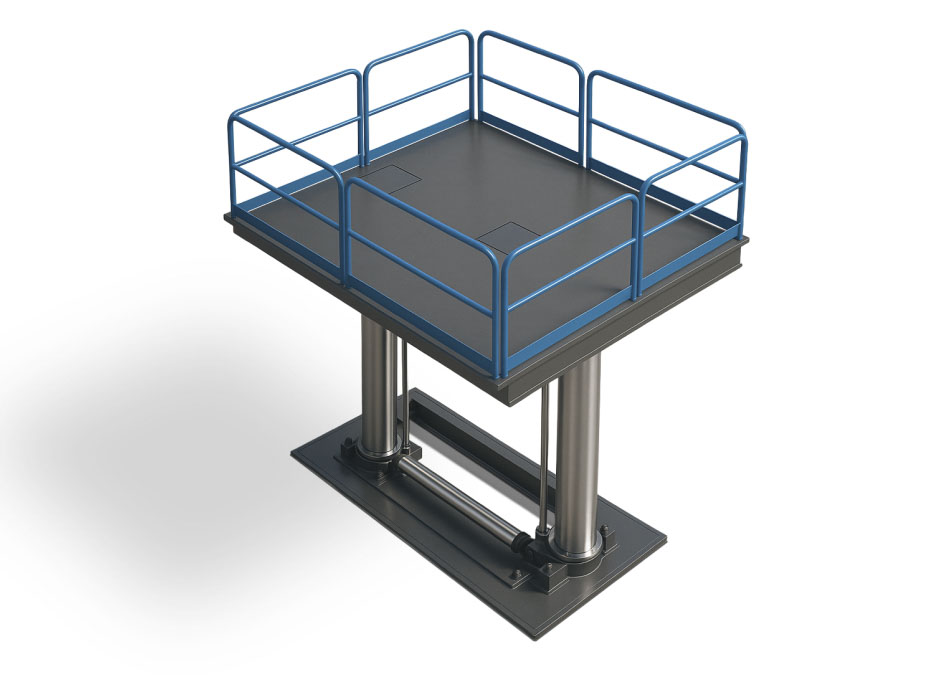

Our Vertical Reciprocating Conveyors (VRCs) are expertly designed to meet the most challenging high-travel and storage requirements.

Autoquip Custom Engineered SolutionsDesigned for the Demands of Industry

Autoquip specializes in solving complex lifting challenges with custom-engineered systems tailored to your exact specifications. From unique load sizes to space constraints, automation needs, or environmental considerations, we design and build solutions that perfectly fit your operation. With over 75 years of engineering excellence and one of the industry’s largest design libraries, Autoquip delivers precision, performance, and problem-solving expertise to every project.

Advantages ofCustom Engineered Lifting Solutions

- Tailored systems for specific loads, heights, environments, and cycles

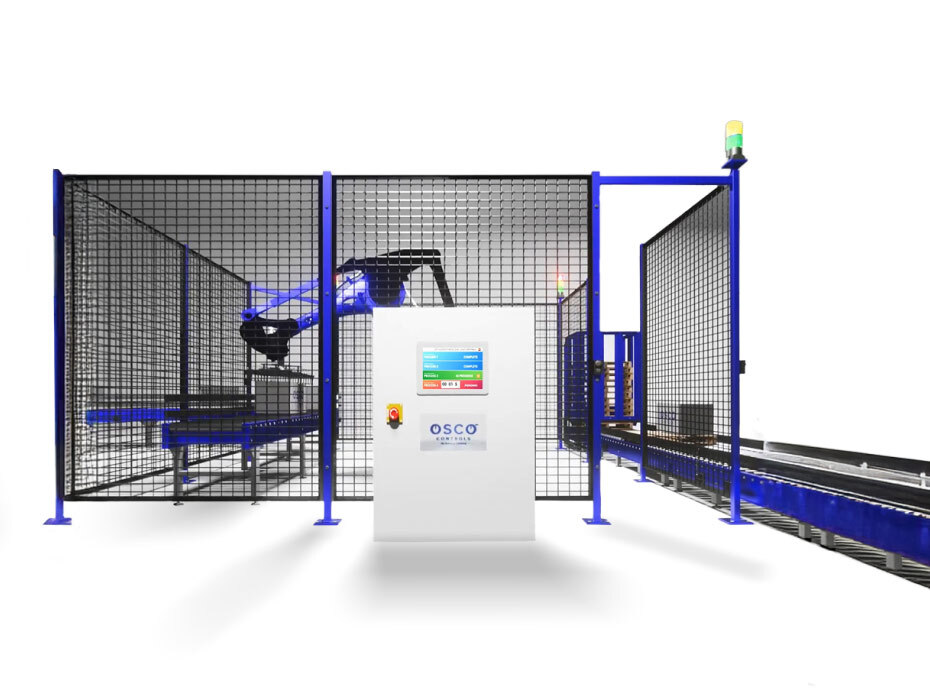

- Seamless integration with automation, AGVs, conveyors, and robotics

- Reinforced structures and premium hydraulic, mechanical, or pneumatic components

- Advanced safety features built to meet or exceed industry standards

- Reliable performance across aerospace, automotive, manufacturing, and defense industries

What to Consider When Customizing Your Lift Solution

Custom equipment starts with understanding your operation and asking the right questions to guide the process.

- What are the weight, shape, and frequency of the loads being handled?

- What is the available space and floor plan of your facility?

- Will the lift integrate with other systems or processes?

- What level of precision or automation is required?

- Are there environmental, cleanroom, or safety compliance needs?

The AutoquipAdvantage

With over 75 years of experience, we understand that one size does not fit all when it comes to industrial lifts. Our highly skilled team of engineers and technical experts maintain a reputation for taking on diverse specialized projects and delivering exceptional results. That’s why our industry-leading design and fabrication services are able to deliver the best solution for any application.

Expect More With Autoquip Custom Solutions

- Engineered from the ground up for your specific application

- Enhanced functionality through intelligent control systems

- Built to integrate with conveyors, robotics, and automated workflows

- Supported by a team with advanced engineering and integration expertise

- Access to a deep catalog of proven designs and customization options

- In-house controls division for smart panels, diagnostics, and programming

ProjectExperience

Autoquip custom lifts are trusted by industry leaders to handle their most critical operations. Explore how our custom solutions have transformed workflows across a wide range of industries.

Frequently Asked Questions

Autoquip designs custom solutions for virtually any lifting need, including mechanical, hydraulic, and high-travel scissor lifts, multi-stage lifts, VRCs (Vertical Reciprocating Conveyors), platform lifts, and more.

If your application has unique size, capacity, travel, or integration requirements that can’t be met with a standard lift, a custom solution is likely the best option. Our sales and design team can help evaluate your project to determine the right path.

To begin, we typically need details such as load capacity, platform size, vertical travel distance, lifting speed, duty cycle, environment (indoor/outdoor), and any special features or constraints (e.g., automation, safety, footprint limitations).

Yes, one of our strengths is engineering lifts that integrate with existing equipment, controls, or structural elements to fit seamlessly into your operations.

We’ve designed lifts with capacities ranging from a few hundred pounds to over 100,000 lbs. We’ll engineer the lift to match your specific weight requirements.

Absolutely. We can integrate advanced control systems, sensors, safety features, and automated functions for precise and efficient operation.

Yes. We offer full engineering services, including 3D modeling and detailed drawings available through our Autodocs customer portal.

Explore More Autoquip Solutions

Get In Touch With Our Experts

Ready to improve your workflow? Contact our team to start your project or request a quote today.

Get A Quote